I can't remember when Marty last posted his method on myLargescale.Com, but I have been using it for a while and really like the way the track looks when finished. This method is fast and easy. It can be done before laying track, or after the track is in place.

On each of the following images you may click them for a Super Size image (1024 pixel wide - aprox. 100K)

- Mask the track

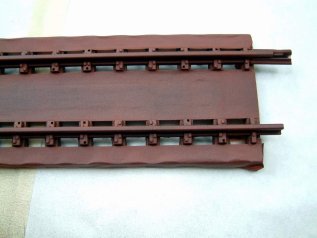

- Spray on Ruddy Brown Primer

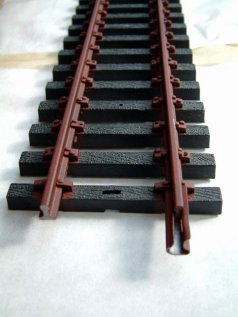

- Spatter on Semi-Flat Black

- Remove the masking

- Clean the rail tops with Lacquer Thinner

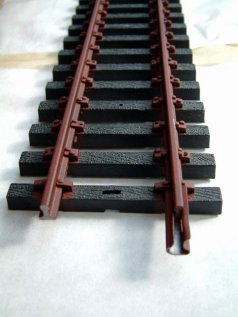

First run a line of tape down the outside of one rail. Butt the tape up tight to the tie plates.

After you have laid the tape down the entire length of the track section, fold it down over the ends of the ties.

Next run a line of tape down the inside of one rail, butting the tape tight against the tie plates.

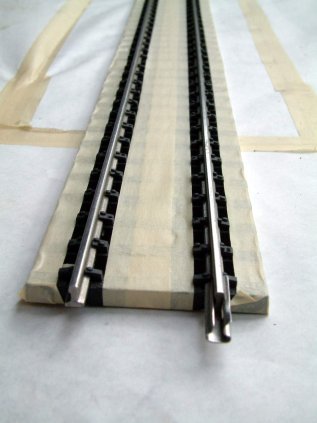

Shake your Ruddy Brown Primer for a few minutes then lay one even coat along the inside of one rail, keeping the can about 8-10 inches from the rail and at a 90 degree angle to the rails. Repeat for the outside rail.

Paint the other side the same way by going to the other side of the track, or turning the track on your table.

One coat might be enough, but I never skimp on paint. After 30 seconds or so I go back and repeat the process for a second coat.

Application of Ruddy Brown Primer is now complete.

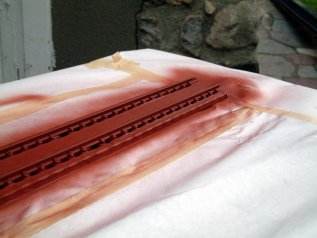

I spray quickly from a distance at least twice normal, like 18-24 inches. Notice that the color is now more brown-like but it still has some oxide color. I sometimes go back and hit it again in short random bursts to simulate oil drips.

It is not important to get an even color. Color can, and should, vary over the length of a section.

Remove the tape soon as the paint is dry to the touch, about 5 minutes.

Lacquer Thinner will dissolve Krylon in just a few seconds. Use a cotton cloth and wet it (don't soak) with lacquer thinner. Work in small sections, about 8 inches at a time. Get the rail top wet with thinner and keep rubbing lightly, turning the cloth to a clean spot often. Within a few seconds the paint will dissolve and wipe right off. Don't rub hard and don't scrape. Let the thinner do the work. Wet the cloth again if it is working too slow. Once you get the hang of it, the job goes quickly with very little effort.

For sidings or "dead" track you may want to leave the tops painted, or only remove some paint as in the photo on the right.

Click the Super-Size link and notice the wide variety of colors you can achieve.

For fun, I keep an old rusty spike handy as a color reference.

On the right is a before & after comparison. Quite a difference, No?

For masking I am using Butcher Paper because I have a roll. You could use newspaper or any other kind of paper that isn't absorbent.

I roll out and cut a length of paper, then run tape down one edge, leaving some adhesive exposed.

Tape between the rails tape as we did above, using two lengths of tape butted against the tie plates, as shown on the right.

If there is any breeze, put some weight on the paper, and tape down as needed to keep it in place.

I chose to mask a hard line at the end of this section to photograph the before/after. Normally I would mask a foot or so beyond where I was going to stop, and next time just blend with the previous section.

If you do mask a hard line this the black will be very difficult to match. Similar to painting sections, you will need to blend the joints later.

Break the work up into 4-5 foot sections and just blend each section together.

One coat might be enough, but I always do two. After 30 seconds or so, go back and repeat the process for a full second coat.

Apply a spatter coat of Semi-Flat black using the technique in the first section of this tutorial.

The photo on the right is the result of my ' short burst splatter' technique to simulate oil drips and stains.

Clean the rail tops with lacquer thinner as described in the first section.

WOW. Doesn't that look one heck-of-a-lot better :]

You may have noticed that this method gets some paint on the ties (and ballast if you paint in-place). I feel that this is a minor trade-off for the simplicity of the masking technique. Most of it will disappear in the ballast and the rest is barely noticeable from a few feet away. But of you are a real rivet counter, it will bother you. In that case you should carefully mask your track, before it is hand laid. You'll have superb looking track when you are done, but I will have been running trains for months while you paint and lay track.